Chemicals and additives to maximize the biogas process: Cleaners

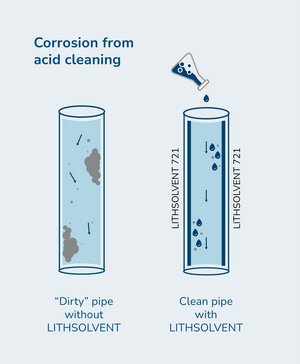

Application: Despite scale preventers such as KEBOPLEX 138, stubborn deposits may form over time in biogas plants that require thorough cleaning. KEBO’s LITHSOLVENT cleaners are specially formulated to directly remove inorganic deposits and mineral incrustations.

LITHSOLVENT cleaners ensure the thorough removal and restoration of the system efficiency, especially in heat exchangers, piping, and evaporators.

Application format: LITHSOLVENT cleaners are circulated as cleaning solutions during maintenance intervals to dissolve deposits and restore the cleanliness of the plant components. This ensures the heat exchanger and evaporator functionality, reduces energy loss, and lowers operating costs.

Inhibited cleaning solution with a good environmental profile for a safe industry.

While continuous and thorough cleaning is essential in industrial processes, it often presents environmental and safety challenges.

In biogas plants, for example, mineral deposits can form in the pipes, heat exchangers, and other components that can affect the operation of the plant.

Our LITHSOLVENT cleaner 721 is an innovative solution.

The inhibited cleaning concentrate is based on environmentally friendly methanesulfonic acid (MSA).

- High cleaning power

- Readily biodegradable, colorless, and odorless

- Stable up to 90 °C and free from nitrogen and halogen compounds

The products shown on our website are only a selection of our entire product range. There is no universal remedy for the rapid removal of impurities. Some can be removed well with alkaline agents, others better in the acidic range. The large variety of conceivable cleaning problems and the large number of additives, inhibitors and ready-to-use cleaning solutions offered by us make it advisable to obtain detailed advice before starting cleaning.

The same applies to inhibitors, defoamers, scale preventers, corrosion inhibitors, pickling inhibitors, etc. Depending on the plant, material, product and the type of boiler/cooling water is used, different individual challenges arise. We are well equipped for them.

Talk to us, we will be happy to help!

On request, we can analyze deposits in our laboratory and develop a cleaning strategy based on our many years of experience, taking into account the conditions on site.