Chemicals and additives to maximize the biogas process: Defoamer

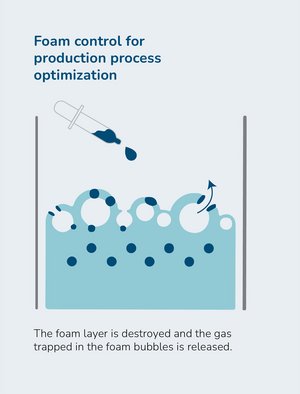

Application: In biogas plants as well as in municipal facilities such as those in the food and beverage industry, decomposition of organic substrates and high microbial activity can cause unwanted foaming, especially in fermenters and digesters. This foam can affect the efficiency of the biogas process by interfering with gas production and circulation.

The KEBOSPUM series with the specially formulated KEBOSPUM BWS is designed to effectively prevent foam formation and dissolve existing foam accumulation without disturbing the biological activity in the fermenter.

Application format: KEBOSPUM BWS is added in small amounts directly to the fermenter or substrate system. The product acts quickly and prevents the formation of a stable foam layer. Continuous operation ensures that biogas production is not compromised and provides a stable process.

Our recommendation: KEBOSPUM BWS in biogas production

- Formulated on plant base: The defoamer is based on natural plant oils, making it an environmentally friendly solution.

- Effective foam control: Fights foam caused by foam-forming substances such as saponins, proteins, and extracellular oligosaccharides (especially in beets).

- Quick foam control: Foaming surfactants immediately reduce surface tension and destabilize the foam.

- Optimal surface effect: The high oil content ensures that the defoamer always remains on the surface, where it develops its maximum effect.

- Safeguarding microbial activity: The high oil content prevents the product from entering the cells. As a result, the growth and productivity of microorganisms is not affected.

- Cost efficiency: The use of KEBOSPUM BWS optimizes resource utilization and reduces the need for additional process agents. This lowers the operating costs and improves product quality.

The products shown on our website are only a selection of our entire product range. There is no universal remedy for the rapid removal of impurities. Some can be removed well with alkaline agents, others better in the acidic range. The large variety of conceivable cleaning problems and the large number of additives, inhibitors and ready-to-use cleaning solutions offered by us make it advisable to obtain detailed advice before starting cleaning.

The same applies to inhibitors, defoamers, scale preventers, corrosion inhibitors, pickling inhibitors, etc. Depending on the plant, material, product and the type of boiler/cooling water is used, different individual challenges arise. We are well equipped for them.

Talk to us, we will be happy to help!

On request, we can analyze deposits in our laboratory and develop a cleaning strategy based on our many years of experience, taking into account the conditions on site.