Chemicals and additives to maximize the biogas process: Scale preventers

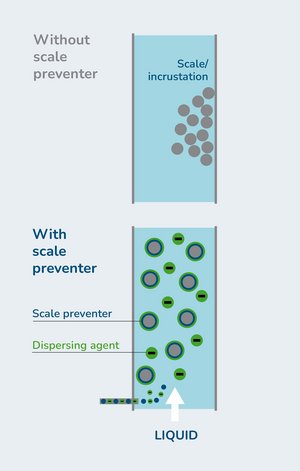

Application: Deposits and incrustation in evaporators, piping and heat exchangers, which affect the efficiency of the biogas process, are a frequent problem in biogas plants. The scale preventer is used to prevent the formation of such deposits in the first place.

KEBOPLEX 138, for example, contains a special mixture of modified polyacrylic and phosphonic acids. These acids have a stabilizing and dispersing effect. Even at low doses, the product effectively prevents calcium deposits and specifically binds to seed crystals to prevent the growth of deposit-forming crystals.

Application format: KEBOPLEX 138 is added using a dosing system in areas of high turbulence, such as upstream of pumps, in order to ensure good distribution in the system.

KEBOPLEX 138: Versatile protection for biogas plants, service water, and recooling systems

Ideal for biogas plants where high levels of calcium oxide in the process often cause stubborn deposits. The special formula of modified polyacrylic and phosphonic acids provides stabilizing and dispersing properties that specifically prevent calcium carbonate and calcium sulfate deposits.

KEBOPLEX 138 ensures stable and efficient processes.

- Highly effective: KEBOPLEX 138 prevents calcium carbonate and calcium sulfate scaling.

- Flexibility: KEBOPLEX 138 adapts to changing conditions thanks to its effectiveness in different pH ranges.

- Low consumption: Sub-stoichiometric dosages lower the chemical consumption (threshold effect).

- High dispersing power: KEBOPLEX 138 remains stable and effective even under high turbidity conditions.

- Specific crystal binding: The ingredients attach to submicroscopic seed crystals and prevent their growth.

- Efficient dosing: 10–20 ppm is sufficient to prevent deposits effectively.

These properties make KEBOPLEX 138 a suitable solution for the specific challenges in biogas plants, especially for preventing incrustation and deposits in pipes and other plant components.

The products shown on our website are only a selection of our entire product range. There is no universal remedy for the rapid removal of impurities. Some can be removed well with alkaline agents, others better in the acidic range. The large variety of conceivable cleaning problems and the large number of additives, inhibitors and ready-to-use cleaning solutions offered by us make it advisable to obtain detailed advice before starting cleaning.

The same applies to inhibitors, defoamers, scale preventers, corrosion inhibitors, pickling inhibitors, etc. Depending on the plant, material, product and the type of boiler/cooling water is used, different individual challenges arise. We are well equipped for them.

Talk to us, we will be happy to help!

On request, we can analyze deposits in our laboratory and develop a cleaning strategy based on our many years of experience, taking into account the conditions on site.