Specialty chemicals in cane sugar production

Various chemical products from the same product groups as in the beet sector are also used in cane sugar production. Nevertheless, there are some differences in the formulation, which by their nature are focused on the raw material cane sugar.

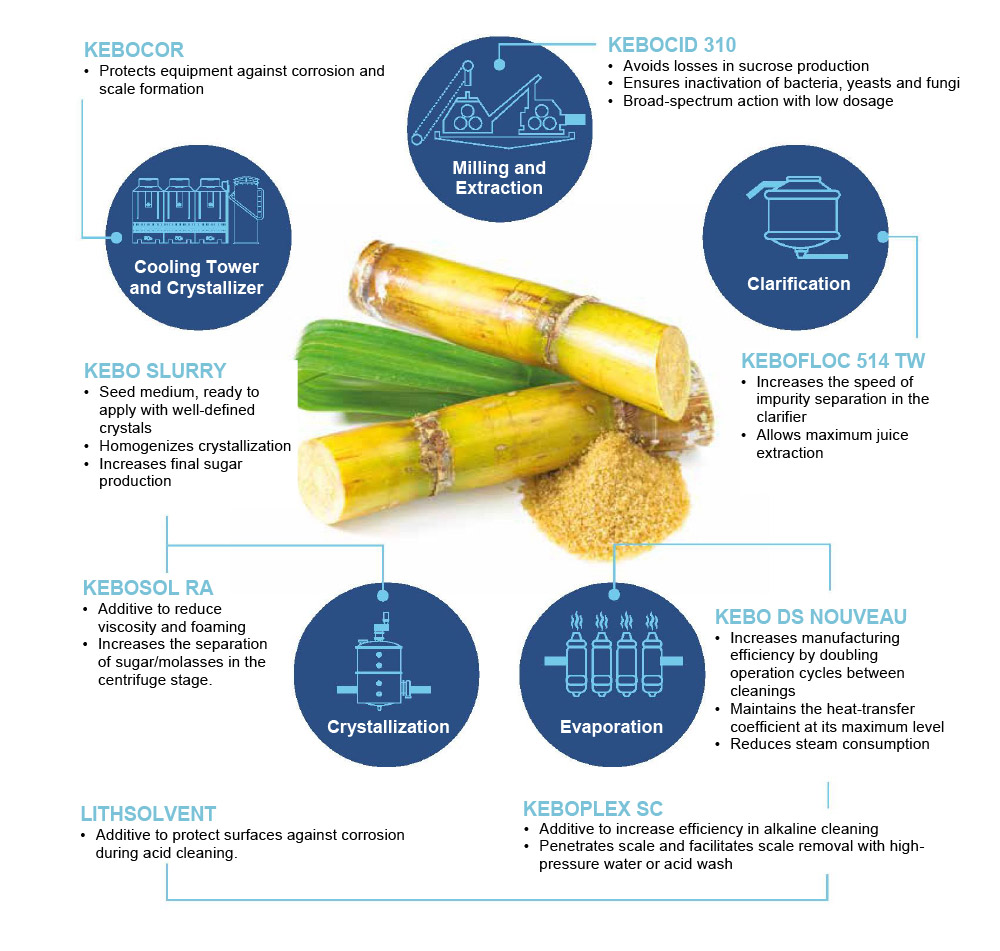

Products for cane sugar production

In the cane sugar industry, intermediate cleaning has been unavoidable up to now due to the special juice properties. In the alkaline treatment, acid-insoluble calcium compounds – such as calcium oxalate and calcium sulfate – are converted into acid-soluble calcium carbonate.

The strongly alkaline solution, due to the caustic soda component, dissolves degraded organic substances well.

KEBO started very early to recommend the soda-etch alkaline cleaning process and to improve it by additives. The effect of soda and caustic soda alone is not effective enough. The process is often time-consuming, as layers that are difficult to permeate prevent further implementation of the scale. Only the addition of dispersants and surfactant activators completes the process, so that in the vast majority of cases alkaline cleaning is sufficient.

Effective principle of KEBO alkaline cleaning: The success depends on the penetrating conversion of the poorly soluble components of the scaling and its thereby enabled disintegration or its lifting from the pipe wall, with sufficient reaction speed. The transformation of, for example, calcium oxalate into calcium carbonate is associated with a volume change in the crystal structure. The stresses that occur in this process can result in individual layer levels lifting off from each other or even from the wall.

Special defoamers are also used here, as foaming can occur in evaporators, crystallizers and other equipment, which could impair efficiency.

Clarifiers are also used to help clarify the raw juice by aggregating fine particles and turbidity in the juice and making them easier to separate. This clarifies the raw juice and removes impurities before further processing.

Milk of lime, a suspension of calcium hydroxide in water, is often used to adjust the pH of the raw juice. The milk of lime increases the pH of the raw juice and prevents acidification. It also contributes to clarification and assists in the removal of undissolved substances in the juice.

Decolorizers are used to remove unwanted colorants from the juice that may be produced during the sugar manufacturing process and affect the quality of the final product. The use of decolorizers helps to improve the color of the sugar and achieve a brighter end product.

To prevent the formation of scale or lime deposits in the evaporators, antiscalants (scale preventers) are used. Such scaling can affect evaporator efficiency, so controlling them is critical for smooth operation.

Crystallization aids are used to affect crystal growth during sugar formation and to control the size, shape and homogeneity of sugar or sugar crystals. This is crucial for the quality of the final product and the crystallization process.

The targeted use of these chemical products optimizes cane sugar production and improves the quality of the sugar produced, while protecting the equipment and extending its life.

The products shown on our website are only a selection of our entire product range. There is no universal remedy for the rapid removal of impurities. Some can be removed well with alkaline agents, others better in the acidic range. The large variety of conceivable cleaning problems and the large number of additives, inhibitors and ready-to-use cleaning solutions offered by us make it advisable to obtain detailed advice before starting cleaning.

The same applies to inhibitors, defoamers, scale preventers, corrosion inhibitors, pickling inhibitors, etc. Depending on the plant, material, product and the type of boiler/cooling water is used, different individual challenges arise. We are well equipped for them.

Talk to us, we will be happy to help!

On request, we can analyze deposits in our laboratory and develop a cleaning strategy based on our many years of experience, taking into account the conditions on site.