Excellent: efficiency and sustainability at KEBO

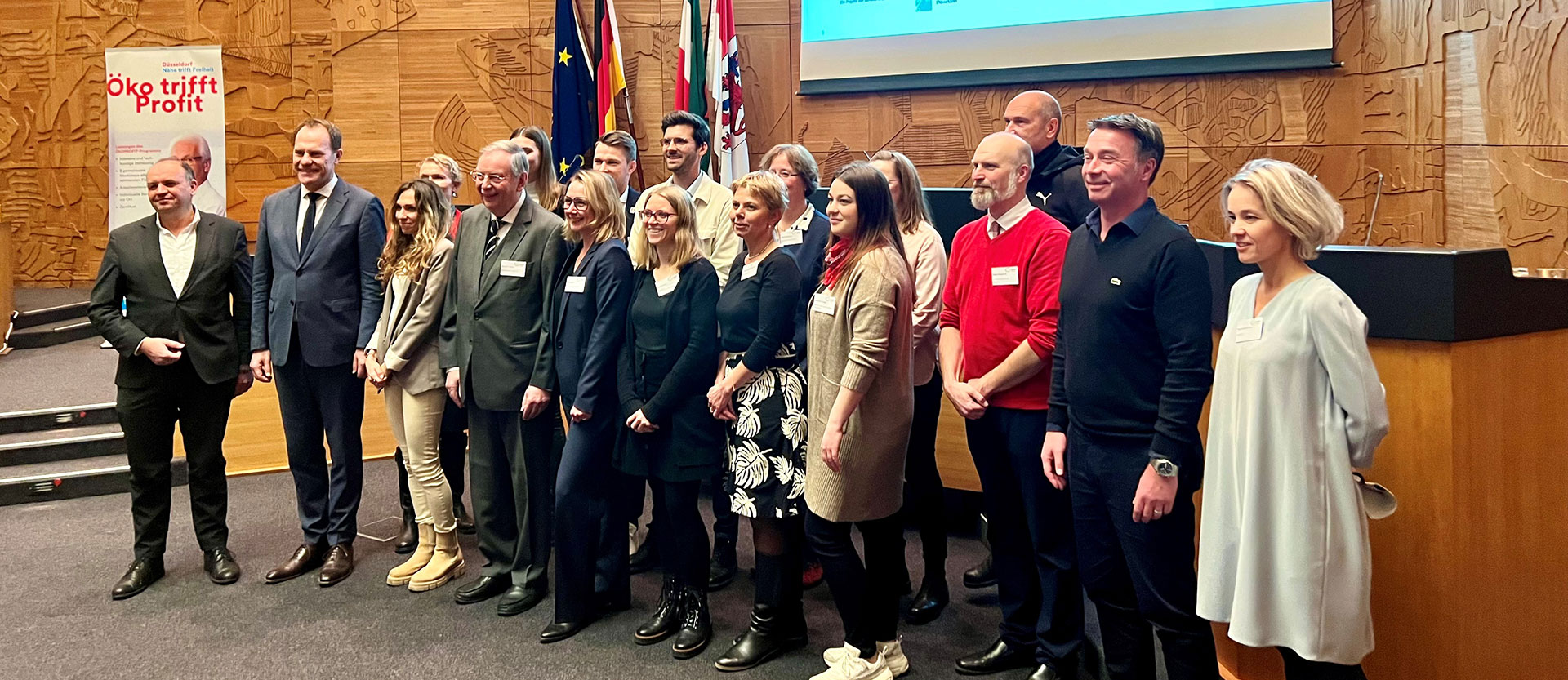

Climate change, the energy transition, and sustainability are the greatest challenges of our time. KEBO is addressing all of these. That’s why we successfully participated in the “Ecoprofit” program of the City of Düsseldorf and worked together with the experts and representatives of the Environmental Agency to develop practical concepts for saving energy and water as well as reducing waste. We are proud to have been certified as an “Ecoprofit 2023” company. We received the award together with 13 other companies from Düsseldorf’s Lord Mayor Dr. Stephan Keller, State Secretary Viktor Haase, and Head of the Environmental Department Jochen Kral.

By using efficient lighting technology, installing water-saving fittings, regulating the air conditioning system, and improving waste separation since November 2022, we succeeded in reducing our operational emissions, conserving natural resources, increasing eco-efficiency, and raising awareness of the environment and sustainability among the entire team. The installation of a photovoltaic system on the roof of the production hall was another highlight for us at the end of the initiative. We now produce almost 50 percent of our total demand and save approximately 30 tons of CO₂-emissions.

However, that’s just the beginning! We will continue to actively consider sustainability in all of our processes in the future. Our specialty chemicals are already helping to increase the efficiency of processes and reduce the energy consumption of all systems.

Our core team for sustainability

We will continue to work on reducing our CO₂ emissions. This means that our core team for sustainability will continue to collaborate with colleagues from all areas to collect ideas and examine their implementation. Their enthusiasm for the project is undiminished. We have an e-mail address that is available to anyone who would like to contribute to this cause. We look forward to your many good ideas!

Return and recycling of our containers

It is important to us to conserve natural resources, recycle materials and avoid waste. This includes our containers.

We return all canisters returned by our customers to the manufacturer for recycling. Drums and IBCs are reconditioned by an external service provider or disposed of if necessary.

The products shown on our website are only a selection of our entire product range. There is no universal remedy for the rapid removal of impurities. Some can be removed well with alkaline agents, others better in the acidic range. The large variety of conceivable cleaning problems and the large number of additives, inhibitors and ready-to-use cleaning solutions offered by us make it advisable to obtain detailed advice before starting cleaning.

The same applies to inhibitors, defoamers, scale preventers, corrosion inhibitors, pickling inhibitors, etc. Depending on the plant, material, product and the type of boiler/cooling water is used, different individual challenges arise. We are well equipped for them.

Talk to us, we will be happy to help!

On request, we can analyze deposits in our laboratory and develop a cleaning strategy based on our many years of experience, taking into account the conditions on site.