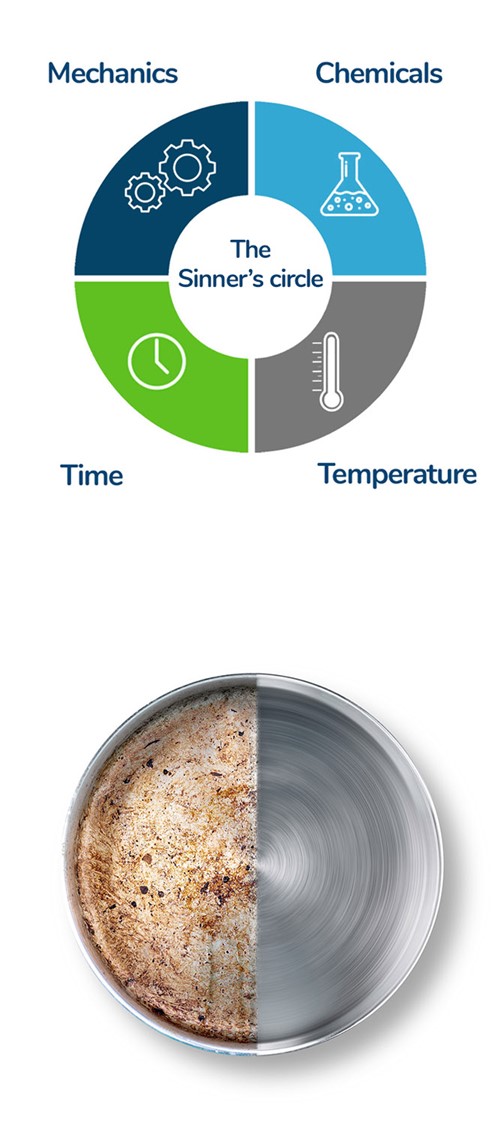

Functionality of the Sinner's Circle

The fascination of Sinner's circle lies in the fact that it always remains closed. A change in one or more factors automatically leads to adjustments in the other factors. For example, if time or mechanics are increased, chemistry or temperature must be adjusted accordingly to achieve cleaning performance. At the same time, a reduction in one factor requires compensation from the others.

The ratio of the factors depends on the type of contamination and the matter to be cleaned. The interaction of all four factors determines the success or failure of the cleaning.

It should be noted:

- Time and temperature influence chemistry and mechanics. For example, a longer exposure time at a higher temperature can improve the effectiveness of chemical cleaning while reducing mechanical stress.

- Chemistry and mechanics influence each other. Choosing the right chemicals can increase the efficiency of mechanical cleaning, while targeted mechanical exposure can support the effectiveness of the chemistry.

This principle becomes particularly clear in the example of dishwashing: If the rinsing time is extended, the cleaning temperature can be reduced. At the same time, more effective chemical cleaning allows to reduce mechanical stress.

At our company, we use the knowledge of Sinner's Circle to develop customized cleaning solutions. Our experienced team specifically combines the four basic factors to achieve the highest cleaning performance and make optimal use of resources.

The products shown on our website are only a selection of our entire product range. There is no universal remedy for the rapid removal of impurities. Some can be removed well with alkaline agents, others better in the acidic range. The large variety of conceivable cleaning problems and the large number of additives, inhibitors and ready-to-use cleaning solutions offered by us make it advisable to obtain detailed advice before starting cleaning.

The same applies to inhibitors, defoamers, scale preventers, corrosion inhibitors, pickling inhibitors, etc. Depending on the plant, material, product and the type of boiler/cooling water is used, different individual challenges arise. We are well equipped for them.

Talk to us, we will be happy to help!

On request, we can analyze deposits in our laboratory and develop a cleaning strategy based on our many years of experience, taking into account the conditions on site.