Highly effective pickling inhibitors: ADACID

The economic benefits in operation are clearly proven:

- Our inhibitors for the protection of metal surfaces during pickling can be used in all pickling plants – with and without regeneration system.

- Further plus points: They avoid over-pickling and reduce acid consumption. The positive consequences: Quality improvements and cost savings.

- Subsequent surface finishes are also not affected.

A plus right away for all ADACID products: the liquid form allows easy dosing.

Here a brief description of our products. For more information please click the product button above.

ADACID 337

When pickling in saline baths, up to 50 °C.

- Features excellent inhibition values even at high Fe levels, while not compromising scale dissolution.

- Contains no hexamethylenetetramine and does not attack rubber and plastics

- Bright and clean metal surfaces are achieved.

ADACID 627

When pickling in saline baths, up to 80 °C.

- Soluble without residue in water and in the pickling bath.

- Low foaming tendency, so that disturbances in the regeneration systems are avoided

- In addition to the inhibitors still contains special dispersants, through which bright and clean metal surfaces are achieved.

ADACID 332

When pickling in sulfuric acid baths, up to 100 °C.

- Soluble without residue in sulfuric acid solutions.

- Is free of chloride and foam, so that disturbances in the regeneration systems are avoided.

- In addition to the inhibitors still contains dispersants and surfactants, through which bright and clean surfaces are achieved.

Effective protection and economic advantages for acid pickling of metal

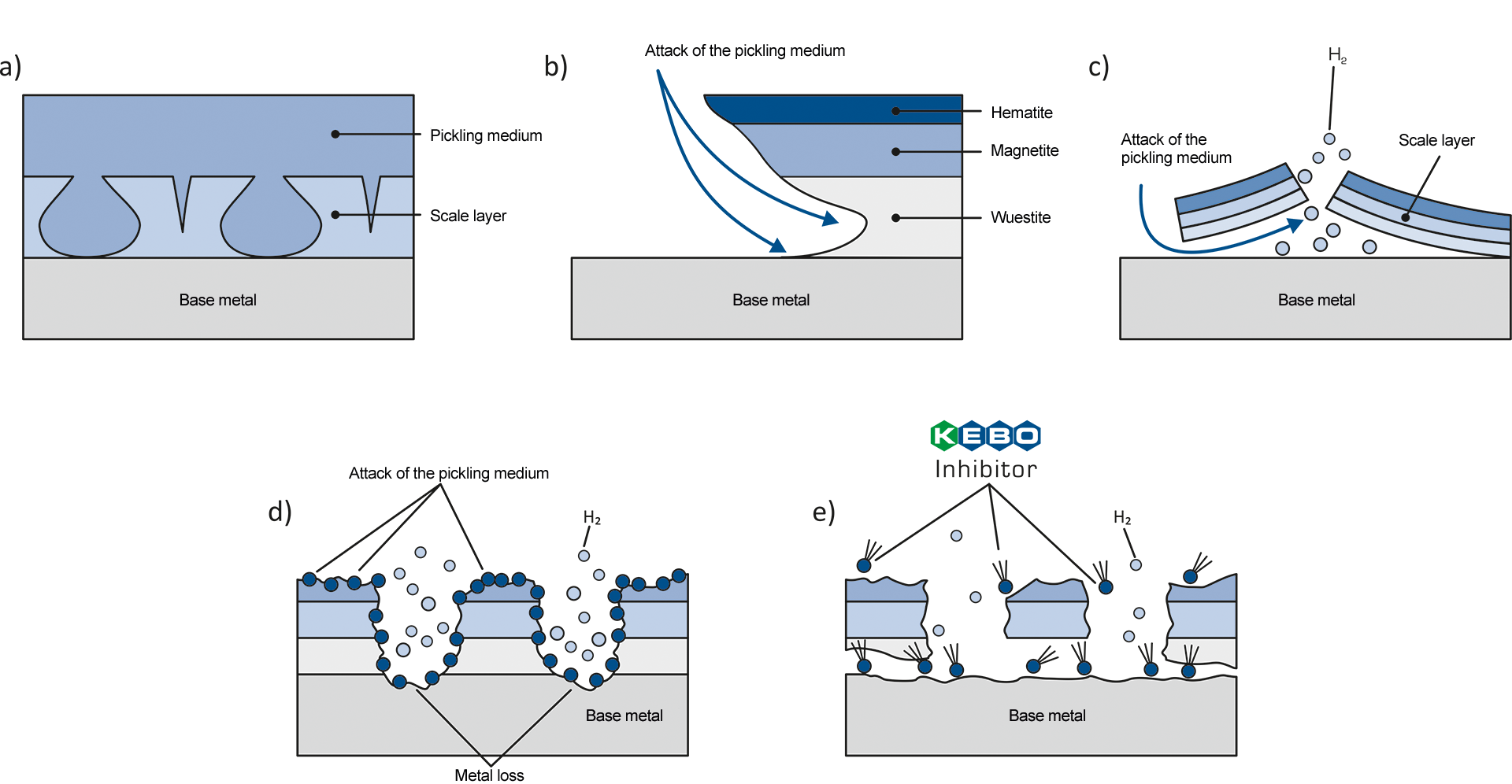

Acids are used to remove the oxide or scale layer and other corrosion products from the metal surface during the pickling process. An oxide layer (scale) is formed on the surface of metal during production and thermal treatment (due to reaction with atmospheric oxygen). This layer interferes with further processing of the material. In the process, the base material is also undesirably attacked. Material losses, unnecessary acid consumption as well as pickling damage, i.e. pore formation, overheating, hydrogen embrittlement, poor pickling atmosphere etc. are the often costly consequences.

This is why ADACID inhibitors have become indispensable in many applications. We develop pickling processes, the fundamentals of which are determined by examining the surface conditions of metal samples.

Manufactured by us for hydrochloric and sulfuric acid, our inhibitors meet the highest requirements. While the metal dissolution rate is lowered, the oxide dissolution rate is only slightly reduced.

The products shown on our website are only a selection of our entire product range. There is no universal remedy for the rapid removal of impurities. Some can be removed well with alkaline agents, others better in the acidic range. The large variety of conceivable cleaning problems and the large number of additives, inhibitors and ready-to-use cleaning solutions offered by us make it advisable to obtain detailed advice before starting cleaning.

The same applies to inhibitors, defoamers, scale preventers, corrosion inhibitors, pickling inhibitors, etc. Depending on the plant, material, product and the type of boiler/cooling water is used, different individual challenges arise. We are well equipped for them.

Talk to us, we will be happy to help!

On request, we can analyze deposits in our laboratory and develop a cleaning strategy based on our many years of experience, taking into account the conditions on site.