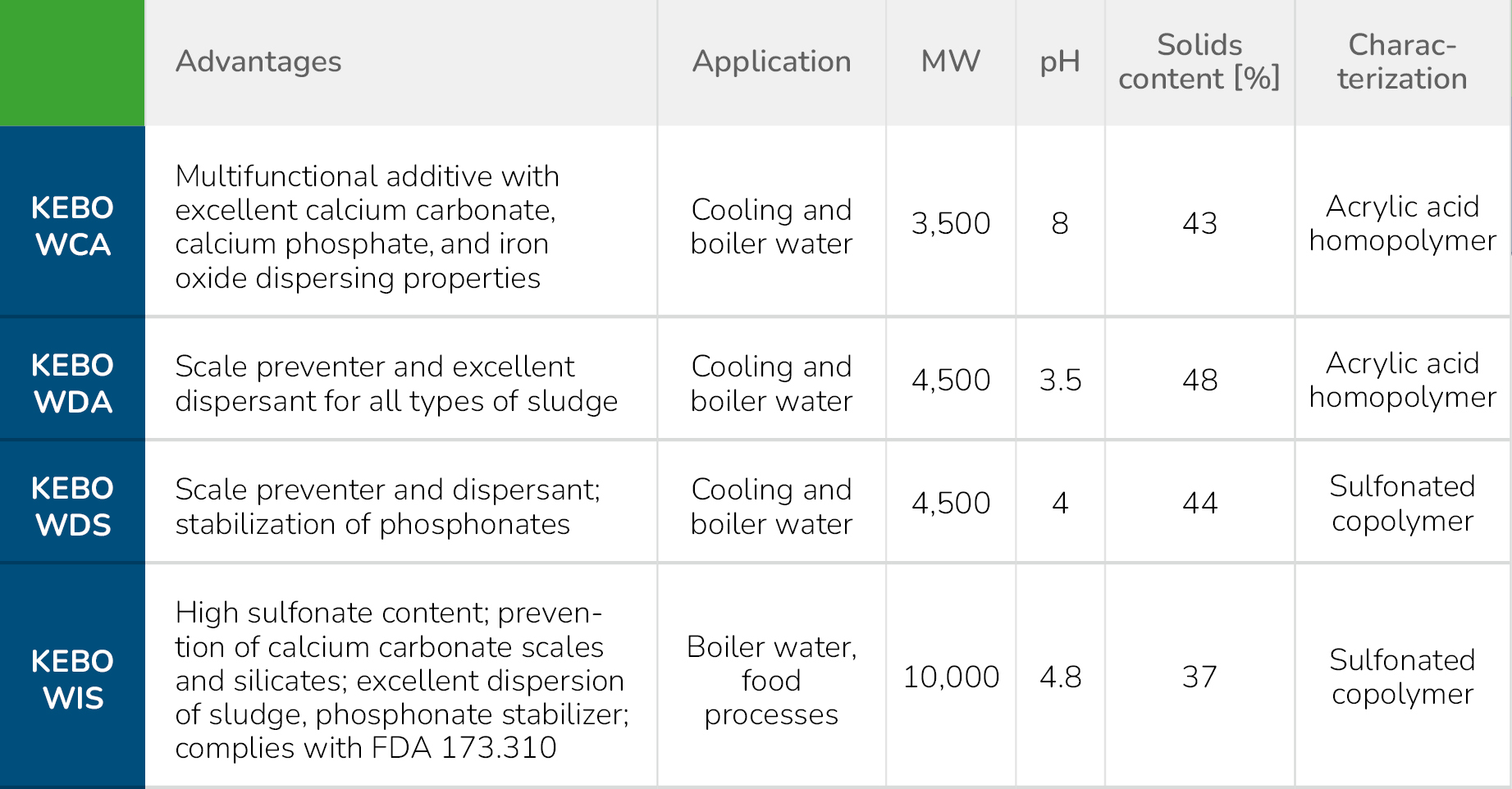

Polymers for scale prevention in cooling and boiler water as well as food processes

In many branches of the industry, cooling circuits are used to dissipate heat by means of circulating water systems. Impurities can accumulate in these circuits, leading to the precipitation of salts. The deposition of salts and other particles on the surfaces can reduce the efficiency of heat transfer and lead to increased operating and maintenance costs.

The water soluble KEBO polymers help to prevent the formation of scale in cooling circuits, boilers, and evaporators. They keep salts dispersed to prevent deposits and can change the structure so that deposits are less stubborn and permanent. Depending on the product, KEBO polymers are effective against calcium carbonate, calcium sulfate, calcium phosphate, silicon dioxide, and silicate. The applications of polymers to prevent scale formation and reduce deposits in cooling circuits, boilers, and evaporators are diverse and cover a wide range of areas:

Industrial boiler and cooling water treatment

Polymers are common components of treatment systems for boiler and cooling water in industrial plants. They are added to the water to prevent the formation of deposits such as scale and limescale by inhibiting crystal formation and agglomeration.

Cooling water circuits

In power plants, refineries, chemical plants, and other industrial facilities, polymers are used in cooling water circuits to prevent deposits on the surfaces of heat exchangers, pipes, and other components. This helps to maintain the efficiency of the heat exchange and reduce energy consumption.

Evaporators and distillation units

Polymers are used in evaporators and distillation systems, particularly in the food and beverage industry as well as in the chemical and pharmaceutical industries, to prevent deposits on the surfaces of the evaporators. This maintains process efficiency and product quality.

Food and beverage industry

In the food and beverage industry, polymers are used to reduce deposits in steam boilers, cooking equipment, steam ovens, and other equipment used in food processing. This is particularly important to ensure compliance with the hygiene and food safety standards.

Heating systems

In hot water and steam heating systems, especially in heating systems, polymers can be used to reduce deposits on the heating surfaces and improve heat transfer efficiency.

The products shown on our website are only a selection of our entire product range. There is no universal remedy for the rapid removal of impurities. Some can be removed well with alkaline agents, others better in the acidic range. The large variety of conceivable cleaning problems and the large number of additives, inhibitors and ready-to-use cleaning solutions offered by us make it advisable to obtain detailed advice before starting cleaning.

The same applies to inhibitors, defoamers, scale preventers, corrosion inhibitors, pickling inhibitors, etc. Depending on the plant, material, product and the type of boiler/cooling water is used, different individual challenges arise. We are well equipped for them.

Talk to us, we will be happy to help!

On request, we can analyze deposits in our laboratory and develop a cleaning strategy based on our many years of experience, taking into account the conditions on site.