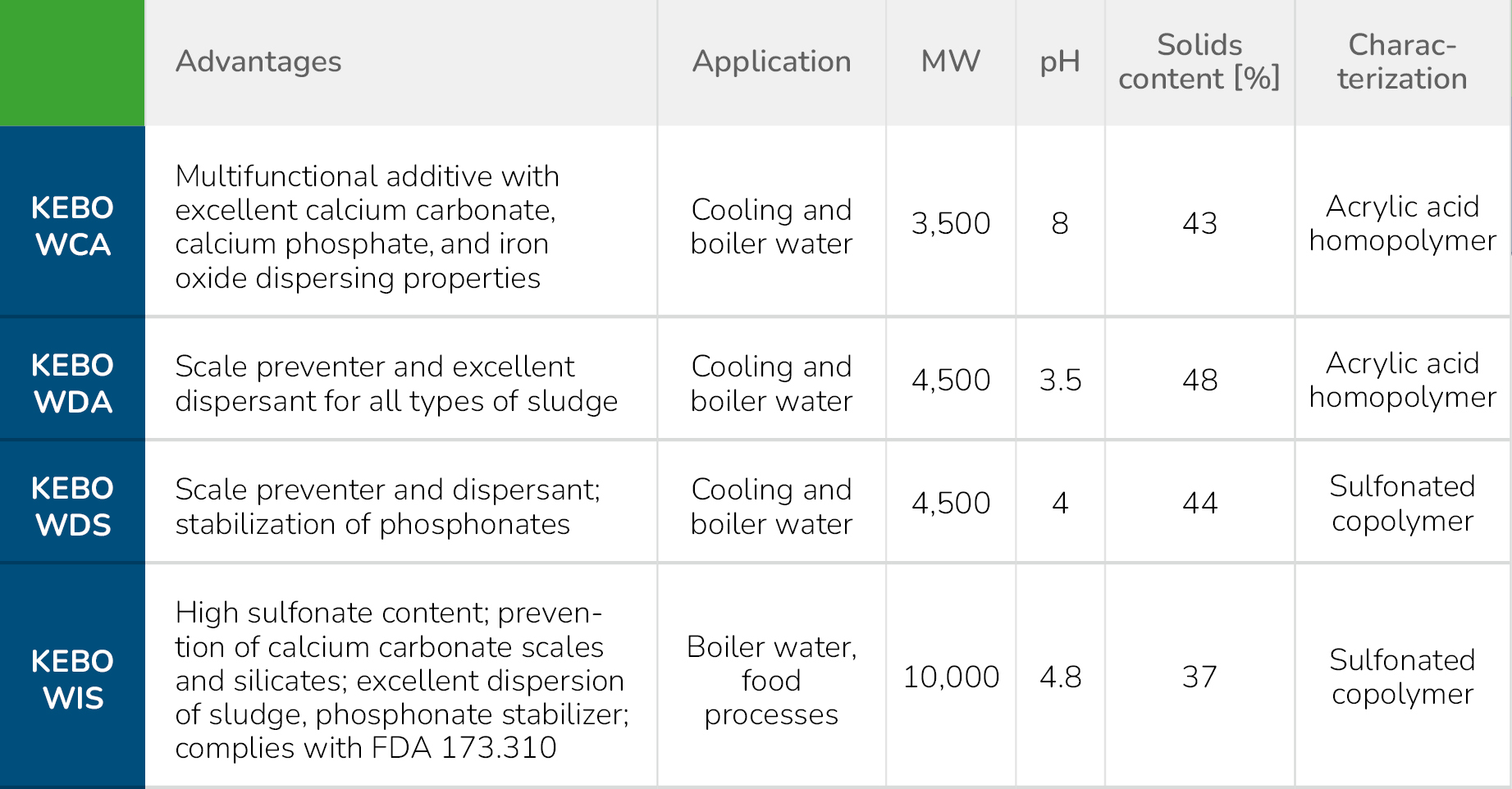

Polymers for scale prevention in cooling and boiler water as well as food processes

In many branches of the industry, cooling circuits are used to dissipate heat by means of circulating water systems. Impurities can accumulate in these circuits, leading to the precipitation of salts. The deposition of salts and other particles on the surfaces can reduce the efficiency of heat transfer and lead to increased operating and maintenance costs.

The water soluble KEBO polymers help to prevent the formation of scale in cooling circuits, boilers, and evaporators. They keep salts dispersed to prevent deposits and can change the structure so that deposits are less stubborn and permanent. Depending on the product, KEBO polymers are effective against calcium carbonate, calcium sulfate, calcium phosphate, silicon dioxide, and silicate. The applications of polymers to prevent scale formation and reduce deposits in cooling circuits, boilers, and evaporators are diverse and cover a wide range of areas:

Industrial boiler and cooling water treatment

Polymers are common components of treatment systems for boiler and cooling water in industrial plants. They are added to the water to prevent the formation of deposits such as scale and limescale by inhibiting crystal formation and agglomeration.

Cooling water circuits

In power plants, refineries, chemical plants, and other industrial facilities, polymers are used in cooling water circuits to prevent deposits on the surfaces of heat exchangers, pipes, and other components. This helps to maintain the efficiency of the heat exchange and reduce energy consumption.

Evaporators and distillation units

Polymers are used in evaporators and distillation systems, particularly in the food and beverage industry as well as in the chemical and pharmaceutical industries, to prevent deposits on the surfaces of the evaporators. This maintains process efficiency and product quality.

Food and beverage industry

In the food and beverage industry, polymers are used to reduce deposits in steam boilers, cooking equipment, steam ovens, and other equipment used in food processing. This is particularly important to ensure compliance with the hygiene and food safety standards.

Heating systems

In hot water and steam heating systems, especially in heating systems, polymers can be used to reduce deposits on the heating surfaces and improve heat transfer efficiency.

Os produtos apresentados em nosso site são apenas uma seleção de nossa linha completa de produtos. Não há um produto universal para a remoção rápida de impurezas. Algumas podem ser bem removidas com produtos alcalinos, enquanto outras respondem melhor a produtos ácidos. É altamente recomendável buscar uma consulta detalhada antes de iniciar a limpeza, devido à grande variedade de problemas de limpeza possíveis e à ampla gama de aditivos, inibidores e soluções de limpeza prontas que oferecemos.<br /> O mesmo se aplica a inibidores, antiespumantes, inibidores de acúmulos, produtos anticorrosivos, inibidores de decapagem, etc. Cada equipamento, material, produto e tipo de água de caldeira/refrigeração utilizada apresenta desafios individuais e distintos. Estamos bem preparados para lidar com esses desafios.

Entre em contato conosco, teremos prazer em ajudar você!

Caso seja de seu interesse, podemos analisar acúmulos em nosso laboratório e desenvolver uma estratégia de limpeza com base em nossa vasta experiência, levando em consideração as condições locais.