Biogas plants that process organic waste especially benefit from KEBO’s product lines:

Take a look at our main product group overviews and product recommendations for biogas plants:

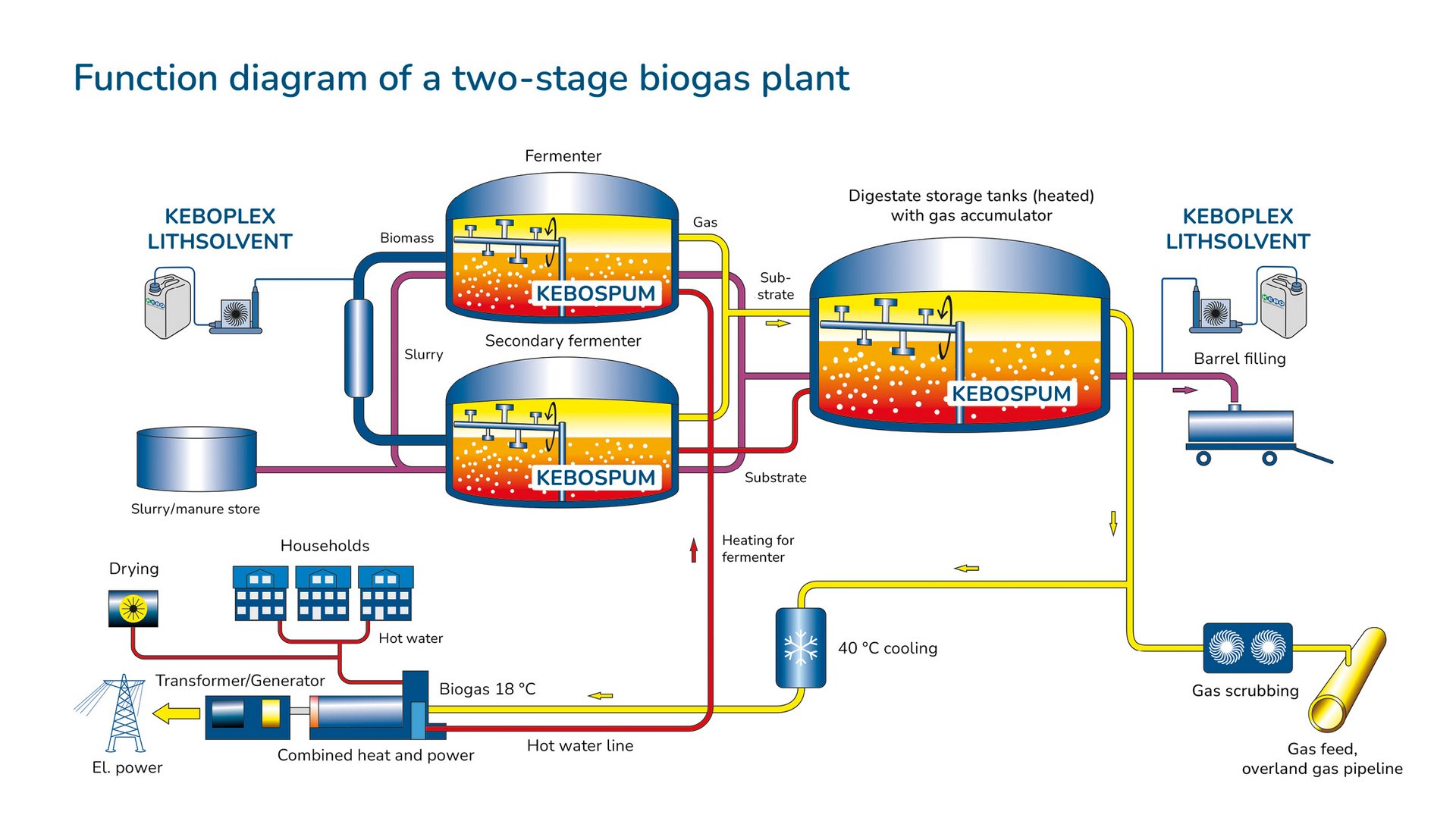

DEFOAMERS

(e.g., KEBOSPUM BWS) eliminate unwanted foam layers and ensure uniform gas production.

SCALE PREVENTERS

(e.g., KEBOPLEX 138) prevent lime deposits in evaporators and heat exchangers and minimize cleaning.

CORROSION INHIBITORS

(e.g., LITHSOLVENT CL4) protect metal components from hydrogen sulfide corrosion.

CLEANERS

(e.g., LITHSOLVENT Cleaner 721) cleaners maintain plant efficiency by effectively removing deposits.

At a glance:

The industrial use of biogas plants is becoming increasingly important. Especially for industries that generate large quantities of organic residual materials

Biogas technology offers a means of utilizing waste products efficiently and reclaiming energy.

In the sugar and ethanol industries, by-products such as sugar beet pulp and molasses as well as lignocellulosic residues such as barley straw or sugarcane bagasse can be converted into valuable biogas. The biogas produced can directly be used as an energy source on site, which significantly increases the plants’ energy autonomy and resource efficiency.

Other industries are benefiting from this technology as well. In the food and beverage industry, many production steps generate waste such as fruit and vegetable residues, peels or marc. By converting to biogas, manufacturing facilities can meet a portion of their energy needs from their own production and reduce waste disposal costs.

Even in the paper industry, where organic sludge is generated during pulp processing, these residual materials can be utilized through biogas processes. Biogas technology is also used in municipal waste treatment plants to generate energy from sewage sludge to meet the plant’s energy needs. The many utilization options show how biogas plants can support the recycling economy while contributing to a stable energy supply.

Industrial biogas plants use different chemical products and additives to maximize the efficiency and stability of the biogas process.

They are used in a wide range of applications because the chemical requirements vary greatly depending on the industry and the type of substances used.

Whether you want to prevent foaming, optimise fermentation processes or remove deposits, we offer tailor-made solutions to meet your specific needs.

Our chemists will assist you on site to help you find the best solution for your biogas plant. Contact us to find out more about how we can help you increase efficiency and stabilise your process!

Our brochure gives you a quick overview of the different applications.

Os produtos apresentados em nosso site são apenas uma seleção de nossa linha completa de produtos. Não há um produto universal para a remoção rápida de impurezas. Algumas podem ser bem removidas com produtos alcalinos, enquanto outras respondem melhor a produtos ácidos. É altamente recomendável buscar uma consulta detalhada antes de iniciar a limpeza, devido à grande variedade de problemas de limpeza possíveis e à ampla gama de aditivos, inibidores e soluções de limpeza prontas que oferecemos.<br /> O mesmo se aplica a inibidores, antiespumantes, inibidores de acúmulos, produtos anticorrosivos, inibidores de decapagem, etc. Cada equipamento, material, produto e tipo de água de caldeira/refrigeração utilizada apresenta desafios individuais e distintos. Estamos bem preparados para lidar com esses desafios.

Entre em contato conosco, teremos prazer em ajudar você!

Caso seja de seu interesse, podemos analisar acúmulos em nosso laboratório e desenvolver uma estratégia de limpeza com base em nossa vasta experiência, levando em consideração as condições locais.